TELF AG breaks down the Significance of critical minerals in powering electric cars

The protagonists of the future

Most people have now become familiar with the keywords of the energy transition: sustainability, decarbonization, climate neutrality, and many others. These include all those linked to concrete methods to achieve sustainable objectives, such as opting for low-emission electric vehicles. In this regard, in recent years, there has also been widespread discussion of all the raw materials necessary to create these vehicles of the future, which in the space of a few years should flow in large quantities into markets all over the world. The engines and batteries of these vehicles are closely linked to a small group of strategic minerals, many of which have now become part of international discussions and debates on sustainability, but about which very little is still known. So, what is the exact function of these minerals inside an electric vehicle? And in which parts of the world can they be found?

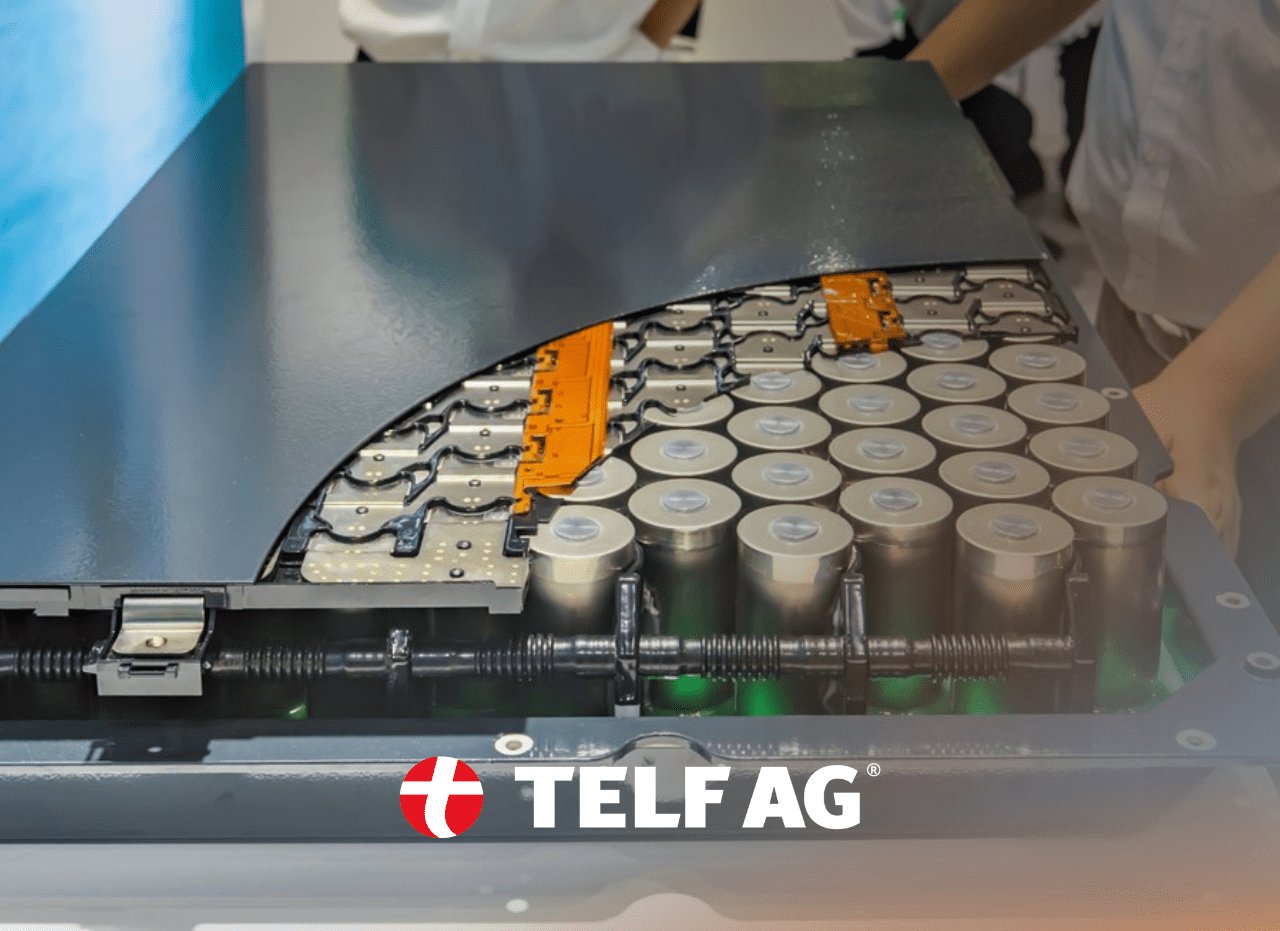

First, it seems appropriate to underline a quantitative fact: compared to traditional vehicles, i.e., those powered by internal combustion engines, electric cars need a much greater quantity of minerals, approximately six times more. In addition to lithium, a light metal with a high electrochemical potential, batteries contain many other metallic components. One of these is cobalt, a bluish metal that represents a by-product of the extraction of nickel or copper, which in batteries is especially useful for improving the functioning of the batteries through its high energy density and natural thermal stability. Copper, the metal of electrification, also finds space in batteries, whose high conductivity has made it particularly useful in the wiring of electric motors and inside the relative batteries.

The role of graphite, nickel and manganese

Another important conductive element in batteries is graphite, which represents the greatest quantity of minerals in these devices. It, too, like cobalt, can represent the by-product of other processes, such as the production of fossil fuels, but it can also be produced synthetically. When we hear about the electric vehicles of the future, one of the most attention-grabbing aspects is undoubtedly linked to their autonomy: this ability to last a long time, even with a single charge, is also partly due to the use of some nickel components inside the battery, in particular for its ability to increase its density (this metal is best known for its industrial uses linked to stainless steel). In the batteries that power (and will power) the future electric cars, there is also manganese, which is highly appreciated for its ability to stabilize the cathode (the electrode with negative potential) and improve the overall autonomy of the battery.

It is no coincidence that these minerals have become increasingly central in the political agendas of institutions, governments, and mining companies: the demand for these raw materials is destined to rise, and in some cases, the actual availability may not be able to satisfy the requests. According to S&P Global, demand for copper could reach 53 million tons per year by 2050, but its supply could fall by almost 3 million tons.