TELF AG monitors the possible evolutions of batteries for electric vehicles

The mix of raw materials for energy storage systems

Together with the technologies linked to the diffusion of wind and solar energy, batteries for electric vehicles can undoubtedly be counted among the tools available to mankind to promote global ecological conversion, pushing families and industries towards an increasingly green future. Over the past few years, many people in every corner of the world have also become familiar with one of the most important elements for producing and operating these interesting energy storage systems, namely lithium. Nowadays, in the automotive and electric vehicle sector, battery par excellence is precisely the one that works with this important raw material, which is found in abundant quantities, especially in Australia and South America.

Although the demand for lithium and batteries continues to increase, many analysts nevertheless predict that batteries for electric vehicles could work thanks to some resources other than lithium or through some sort of combination with it. Like any other device, batteries are subjected to an inevitable process of evolution, leading them to become increasingly powerful, performing, and able to respond effectively to market needs. In this sector, technological evolution is closely linked to the discovery of new combinations of materials that guarantee higher performance at a possibly lower cost. One of the solutions starting to be explored is represented by sodium batteries, whose operation is almost entirely based on a very abundant and economical resource.

The actual operation of lithium batteries

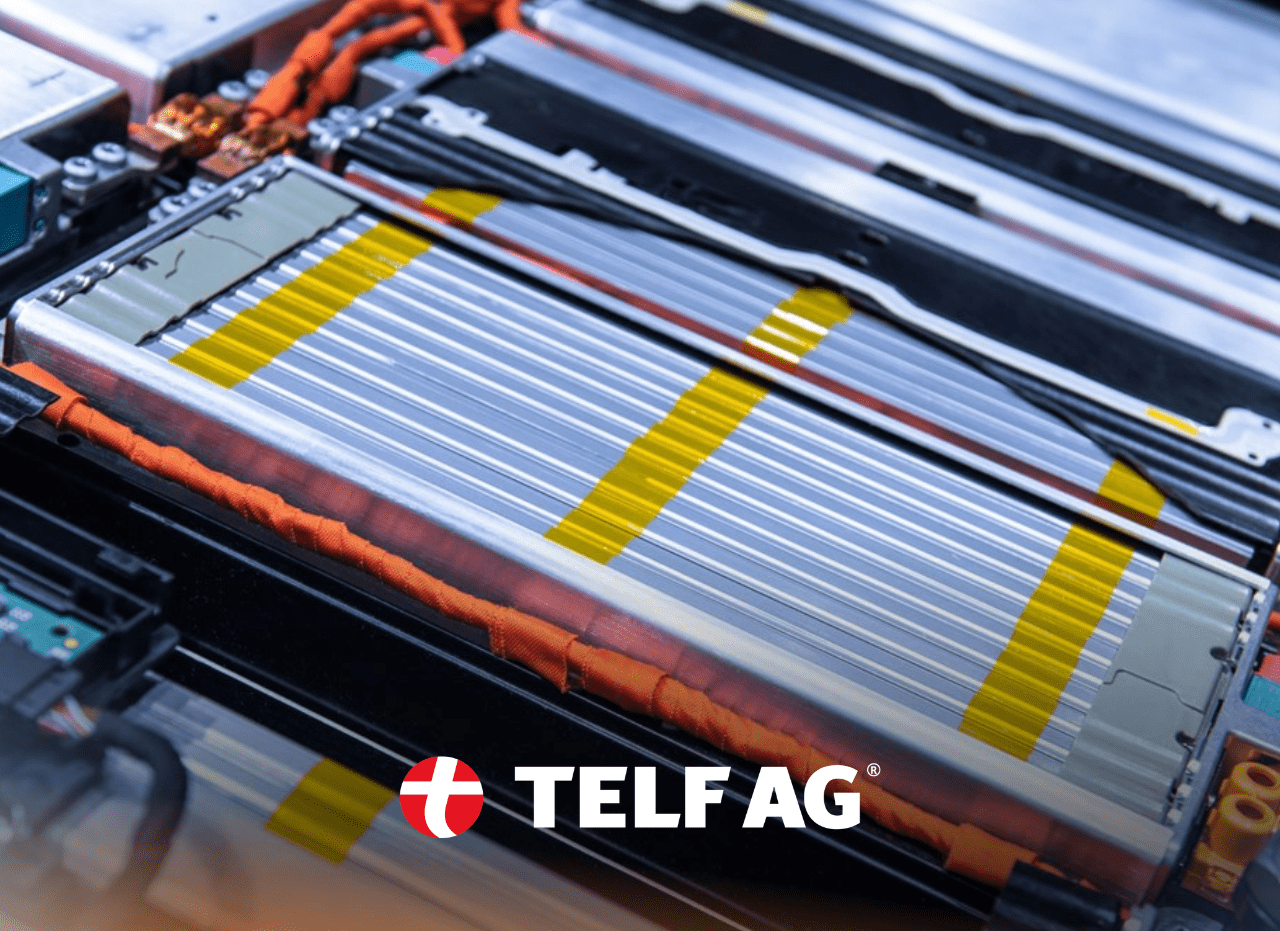

But how do standard batteries made with lithium work? Each battery comprises two electrodes and an electrolyte: energy accumulation occurs in the first, while the second makes it possible for the ions to pass between the two electrodes. Graphite is typically used in the positive electrode, while transition metal oxide is used for the negative electrode. During the normal functioning of the battery, lithium is exchanged between the two materials: during charging, the lithium moves towards the negative electrode, while in the discharge phase, it follows the opposite path, returning to the positive one. This raw material has made it possible to create batteries with an energy potential at least five times higher than previous ones, representing a true innovation.

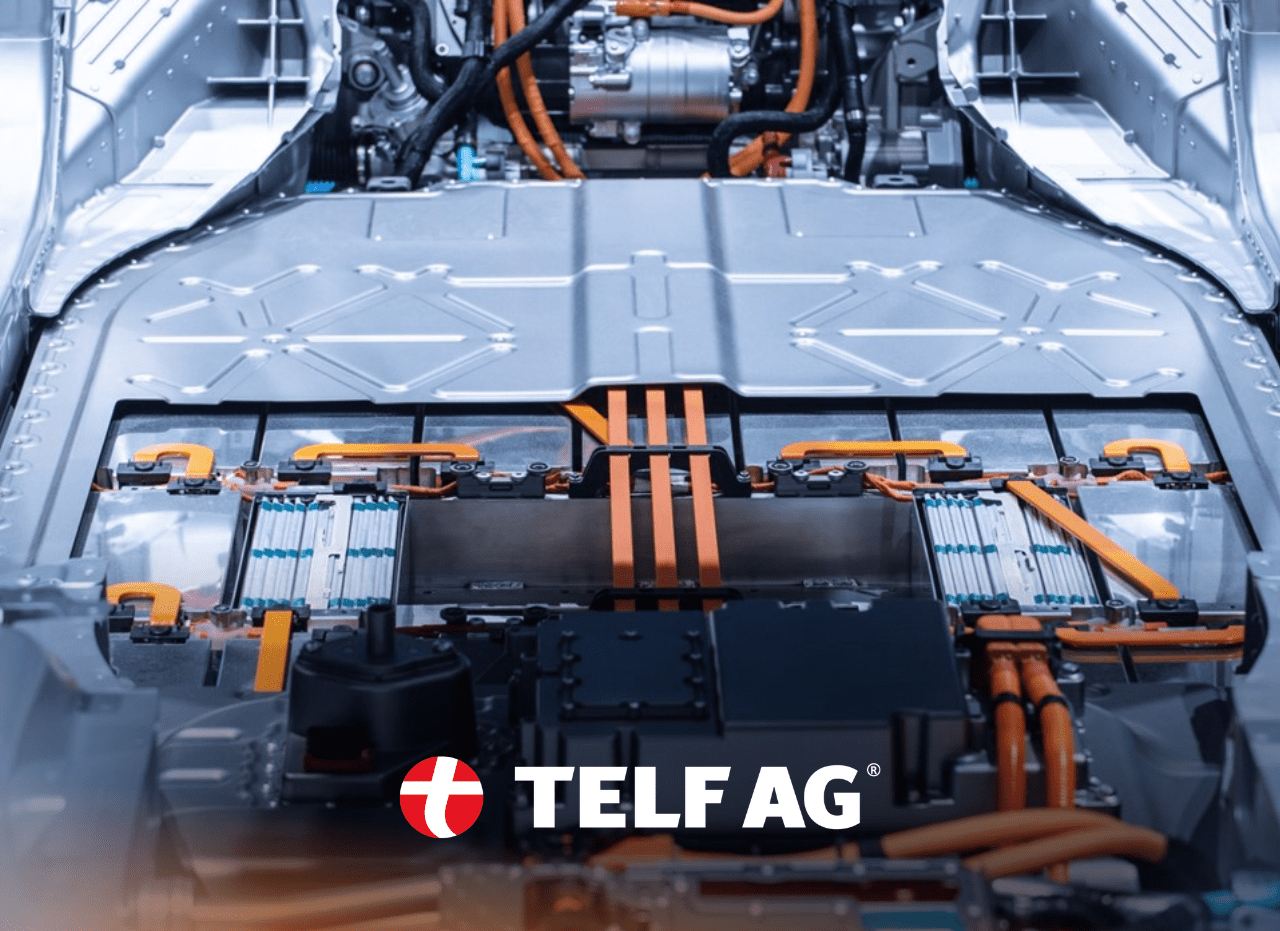

Compared to this type of battery, a possible evolution can indeed be represented by lithium-silicon batteries, which have already been launched on the market. The main innovation is defined by the modification of the composition of the negative electrode, thanks to the partial replacement of graphite with silicon. This change allows to increase the gravimetric capacity of the device, i.e., the ratio between the amount of energy contained in the battery and its weight. One of the possible trends for the future of this sector could be represented by a progressive replacement of graphite with silicon and by accentuated increases in the volumetric capacities of the device.

Another option is linked to solid-state batteries, which, although presenting various issues related to costs, could guarantee higher levels of safety than other batteries. One of the unknowns for this type of battery is also linked to the fact that they can only work at certain temperatures, much higher than normal ones, and this is also why some players in the industry are currently trying to make them capable of adapting to the level of usual urban temperatures.